On behalf of the Ray’cycle Team, I would like to thank all of you for contributing to this project. We are excited to announce that because of the unprecedented participation, we had to raise our goal to a much bigger number. We specifically chose 5000 as our new number symbolically to represent the amount of plastic (in tons) that ends up in the environment. According to Swiss Federal Laboratories for Materials Science and Technology, that is how much new plastic is wasted each year. This is a major problem because this material does not biodegrade and builds up over time.

Of the 8.3 billion tons of plastic that has been produced, 6.3 billion tons has become waste dispersed throughout the planet’s landfills and oceans.

As a population, we have wasted so much plastic because it is extremely convenient to use something once and throw it away without worrying about cleaning it before or after use. This “grab and go” mentality is plaguing the planet as corporations keep up with the demands for “easy” options of packaging – especially for food. Now with the COVID-19 pandemic, single use plastic is the most sanitary option for keeping the public safe.

This is an insanely large number, an unacceptable one in my opinion. What are the implications of this? Even though it is not affecting our lives now, it is possible we will have to deal with the consequences. The state of the environment is depleting everyday due to waste. Ecosystems are unable to support as many species leading to a lack of biodiversity and extinction of many organisms.

Why is plastic the environment’s worst enemy? There are many reasons:

- There is an overwhelming abundance of single-use plastic being produced.

- Plastic is lightweight so therefore it floats and can be carried by the wind.

- This is bad because it makes it impossible to contain plastic waste and it can easily end up polluting ecosystems.

- Plastic can break into “microplastic” which ends up being ingested by animals and endangering species.

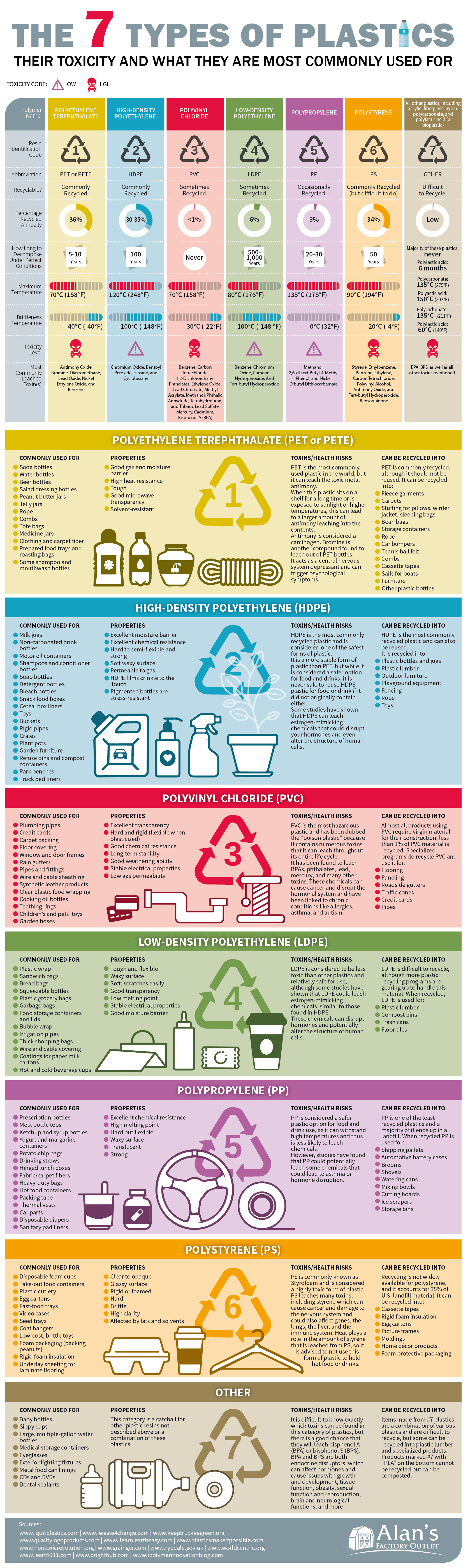

Plastic is a polymeric material that consists of chains of carbon and hydrogen atoms. The material is abundant, cheap, and can be melted down and reshaped with a low amount of heat. There are 7 different types of plastic, classified by resin identification codes. You can see the names and uses of these plastics in the image below.

These numbers were originally assigned in the 1980s to keep plastics separate during manufacturing and reprocessing. There is a misconception that seeing this symbol on plastic makes it automatically recyclable but that is not the case. In the higher numbered resin identification codes, there are more complexities associated with those plastics. Plastics numbers 3-7 are often turned away from many recycling centers and end up in an incinerator, landfill, or the ocean.

Not all plastic can be easily recycled for many reasons:

- More complicated processes get expensive.

- Melting down plastic over and over again depletes its quality/value.

- Needs to be completely clean, chopped up, and melted.

- Recycling bins are often contaminated when it’s food packaging.

As engineers, team Ray’cycle and I are committed to improving the world we live in. One way is by engineering a type of polymer that is biodegradable but functions identically to plastic. Another way is by working to streamline the recycling process to make it more inclusive. One thing we are doing specifically is using SSSP and SSME to recycle plastic films and bags – as recycling centers do not typically accept them. This project will test our ability to repurpose your household items that would have ended up in landfill or oceans anyway. The possibilities are endless but I believe that in the near future a solution will be found to combat this issue.

What can you do to help? I’ll tell you: think outside of reuse, reduce, recycle. Focus on refusing and repurposing. Before buying anything, think to yourself. “Do I really need this?” or “What do I already own that can fulfill my needs?” Also, attempt to repair broken objects before resorting to trashing it. Through this project, we hope to educate everyone on proper recycling techniques so that there is less waste in our world. Obviously, our current society has become dependent on plastic but I think it’s time we abandon that wasteful mindset. By taking time to learn about this, you can help combat the environmental damage done by plastic waste.